SUMINISTRANDO A LAS FUNDICIONES DESDE EL 1943

El socio ideal para las fundiciones de metales. Distribucion en exclusiva de primeras marcas mundiales para el sector de la fundicion

Nuestra Historia en Fundición

Soluciones para la Industria de la Fundición

Desde 1943, somos líderes en suministros para fundición, tanto férrica como no férrica. Nuestra dedicación a la calidad y la innovación nos ha hecho sobresalir en un mercado competitivo. Comprendemos las complejidades de la fundición y estamos comprometidos a ayudarte a alcanzar tus metas con productos de alta calidad y servicio excepcional

0

AÑOS DE EXPERIENCIA

+

0

PROYECTOS ÉXITOSOS

Proyectos que resaltan nuestra excelencia laboral

Nuestros trabajos

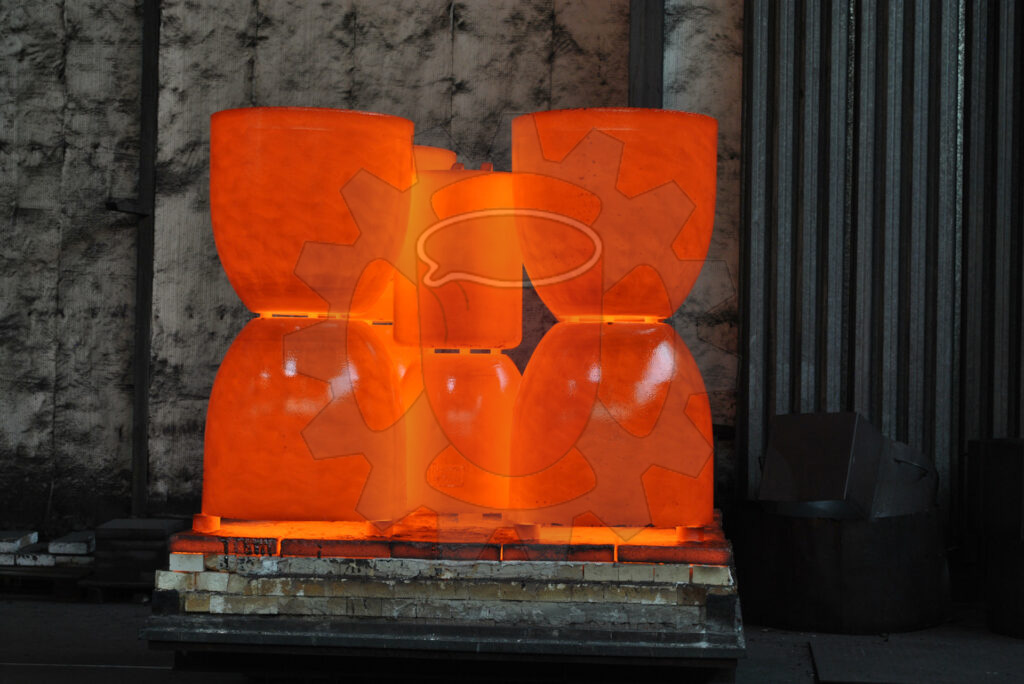

Preformados cerámicos

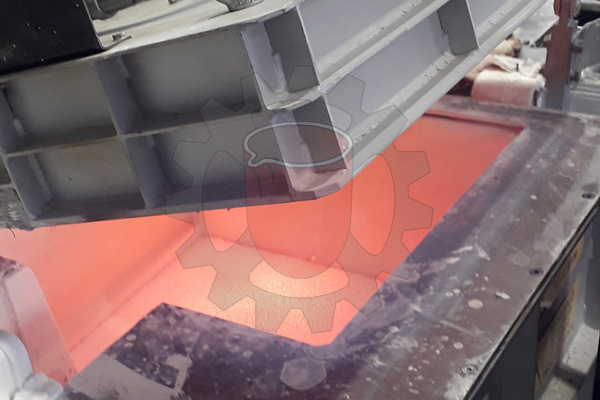

Mesa de colada

6 un. maquinaria de insuflación E.I.F (Eco Injection Flux)

Pintura Nitruro de Boro

Horno Castel Modelo SP-8/2 (BUX-300)

Horno Basculante Castel Modelo SP-12 (TPX-15)

Maquina de desgasificar

Caja Filtrante

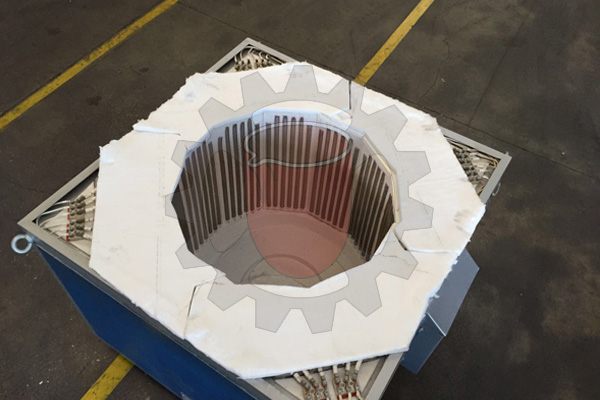

Reparación horno eléctrico

Testimonial

What Our Client Say

Lobortis arcu at suspendisse arcu egestas lectus purus magna interdum aliquam scelerisque.

Ante varius at tortor auctor dui mi eros auctor consectetur cras velit, neque et tellus nulla viverra natoque aliquam, malesuada viverra adipiscing diam eu auctor id tellus.

Mary Kate

In habitant est rhoncus molestie tristique et egestas eleifend elit mauris massa tempus nulla elementum, faucibus pretium nibh vitae ultricies eleifend .

Anna Grace

Scelerisque dignissim semper augue eget turpis dolor, a, mauris lacus arcu dictumst dolor aliquet faucibus suspendisse dolor lobortis faucibus risus, in diam.

Billy Joe

Habitant eget tellus accumsan, interdum vitae vitae aliquet at gravida nulla urna, enim a enim diam tempor accumsan, semper diam id velit netus arcu lectus eros.

John Peterson

Optimiza tu fundición con nuestros productos

La excelencia y el desarrollo continuo de nuestros productos son la clave que permiten mejorar tus procesos.